COLOR SERVICE SRL - AUTOMATIC DOSING SYSTEMS

Color Service is an Italian leading company in the production of automatic dosing systems for any kind of powder and liquid applied in the food industry.

In most cases, the weighing department in the food industry employs operators that manually dose raw materials, resulting in difficult and complex management in terms of the accuracy of the weighing itself.

Our technology is developed to solve problems associated with the manual weighing of any kind of powders and liquids applied in the food industry and it is designed with the aim to get a safe, fast and precise dosing. The goal is therefore the development of high-efficiency systems that allow to minimize the production costs and boost productivity while also improving final product quality, essential for the competition of all companies.

To fulfil the market's demands, Color Sevice offers two solutions of automation: a complete full automatic and a semi-automatic weighing system.

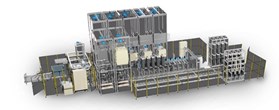

The full automatic system, guarantees High Dosing Accuracy, Batch Traceability and Modularity of storage stations satisfying customer’s permanent and future need. Customer’s products (powders, granules,micro-granules flakes, liquids) are transferred and stored inside dedicated silos of various capacity through high performance vacuum for powders and pump for liquids that guarantee fast loading with low air consumption.

During the dosing, a multi-scale conveyor completely aspirated through a dedicated dust extraction system allows the precise weighing of recipes that can be dosed directly into a bucket or in identified bags created in a completely automatic way: this is a fundamental characteristic that allows each individual recipe to be traced. With the full automatic system all processes are entirely automatized.

On the other hand the semi automatic weighing system can offer a good compromise: the robotic storage of powder products with the manual weighing assisted by PC. In this way the, according to the recipe, the system drop the right box and transfer it to the weighin pisition, where the operator, guided by the PC can dose the product.

An aspect we particularly care about concerns environmental sustainability as well as the health of operators in the workplace. The automation reduces to zero the exposure for operators to dangerous substances, which in certain industrial scenarios, are in direct contact, ensuring absolute control of the dust emitted during the weighing and suction of dispersed components with obvious ecological benefits.

By investing in an automatic dosing system, the customer will be able to benefit from a repeatable production process that runs 24 hours a day, is reliable and fast, in which human error is definitively eliminated and which allows leading to high-quality end products with uniformity features throughout time.

Systems are user-friendly and software is intuitive and easy to use, allowing a quick and easy understanding.

More production in less time, more coordination, reduction of the margins of error in all the processing phases, more energy-saving, fewer wastes and more safety for the operators: all these are concrete benefits that Color Service technology brings to customer’s reality.